I was recently scrolling on social media (I know, Surprising.) and I saw a video of my longtime peer Ryan, over in Massachusetts, doing some Mastic work. I have zero experience using mastic. It just isn’t a “thing” here in rural Wisconsin, but I am always fascinated by the demos and videos I have seen of it in use. For those of you who don’t know already, I am an Asphalt Maintenance geek, and that stuff is what fills most my feeds up. So, when speaking to the editor of this magazine, Brandon, recently at a conference, I asked how I could help create some content for ‘Pavement Magazine’ and he said some content about this very topic would be appreciated. I knew just who to speak with. Luckily, the Asphalt and Asphalt Maintenance Contractor Community are a tight knit group and always open to sharing info, knowledge, and experience. Ryan is no different.

Ryan has been at it for a long time now. Upon asking, I was fortunate enough to have my friend from Premier Sealcoating and Line Striping out of Oxford, Massachusetts join me on the Blacktop Banter Podcast to talk about his use of Mastic and Crack Sealant, along with the pros, cons, and prep for each. Let’s jump into the highlights of that conversation now:

Mastic

What is it?

Ryan explains that mastic is a block, or brick, of asphalt binder and on top of it (inside the box) is a bag of aggregate that gets mixed into the machine with the binder block. Then heated and agitated to create a thoroughly mixed material. It is applied with heated tools to prevent build up and assist with spreading. Keep in mind, it doesn’t have the elasticity of crack sealant rubber.

What is it Used for?

Ryan explains in the interview, that mastic has many uses. Great for patching over “spider-cracks” or shattered areas. Anderson also expressed that failing seams in asphalt and cracks over 1” in diameter are a great problem for mastic to be used on for repairing. He also expressed that it can be used for “smaller” pothole areas, if need be, but keep in mind that mastic is a maintenance item and not a permanent solution. Primary uses are in municipal areas and parking lots.

What do we need to know about getting into Mastic service offerings?

Anderson expressed that, “Prep is Key,” many times during the interview. Stating that making sure the area of service is completely dry, then cleaned very thoroughly to remove any moisture, dust, or particulates, that may inhibit bonding. He also told us that the barrier to entry into offering mastic services is high, as the machines cost more than most of their crack sealant melter counterparts, as well as the material costs.

Crack Sealant

What is it?

Ryan explains that crack-sealant, or “rubber”, is comprised of asphalt binder, rubber bits and other ingredients, as mixtures vary depending on supplier and elasticity. It is primarily applied by hand with pourpots, squeegees, speedbanders or MA-10s when using the DF (Direct-Fire) version. It is melted with oil-jacketed melters when it is the OJ (Oil-Jacketed) version of the material and can be applied by a wand machine, often “pull-behind” in this mode.

What is it used for?

It is primarily used to fill and “band” longitudinal and latitudinal cracks in fractured asphalt pavements, but is also used on fractured concrete as well. It can often be used to fill/cover divots, scars or very small, shattered areas as well. It is not ideal for any patching applications due to the possibility of it sticking to tires or other objects and causing failure. Ideal use for driveways and parking lots, as well as municipal crack-sealing at a larger scale.

What do we need to know about getting into Hot-Crack Sealant service offerings?

Anderson expresses safety and PPE with this material is a must because it is very hot when melted and is commonly used in an asphalt maintenance business, versus mastic, which should also be used carefully and with PPE. As expressed with mastic, Ryan lets us know “Prep is Key” and to be sure any moisture, dirt, vegetation or debris is clear for proper adhesion to existing pavement. Cost varies with different versions or brands of this material but the barrier to entry, to offer this service is much more affordable when compared to mastic.

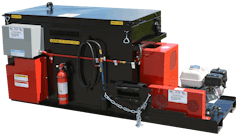

Personally, I have seen a couple of mastic demoes live and most recently at Pave/X with the Crafco Patcher 4. The system and application process in that demonstration seemed to run very smoothly and safely, once the process is understood, and a high-quality machine is the foundation. The area that the Crafco mastic was applied to was too wide and too deteriorated for Crack Sealant to repair.

We personally use a Crafco crack sealant melter/applicator at my asphalt maintenance business Wis-Coat and the process of applying OJ material with that machine, over DF material, is definitely more cost effective and more efficient in certain situations, but we also use DF widely in other situations where the OJ process is less efficient.

I implore you to see what material suppliers and equipment dealers/renters are near you and ask for a demo or information regarding both these services, products, and more. You could be missing out on an opportunity to expand your services and chance to offer more value to your customers.

As always, if you have any insight or criticisms about this article or anything in it (which I have a feeling there will be), please feel free to email us at [email protected] and of course, reach out to us at Blacktop Banter on any form of social media. You can listen to Blacktop Banter anywhere podcasts are available, and the Video Versions are always posted to the Blacktop Banter YouTube Channel.

![Screen Shot 2023 01 04 At 5 23 30 Pm[35]](https://img.forconstructionpros.com/files/base/acbm/fcp/image/2023/01/Screen_Shot_2023_01_04_at_5.23.30_PM_35_.63bc42696de27.png?auto=format%2Ccompress&fit=crop&h=135&q=70&w=240)

![Patcher4 4edited[66]](https://img.forconstructionpros.com/files/base/acbm/fcp/image/2022/10/patcher4_4edited_66_.63602ddb9e727.png?auto=format%2Ccompress&fit=crop&h=135&q=70&rect=0%2C123%2C1920%2C1080&w=240)